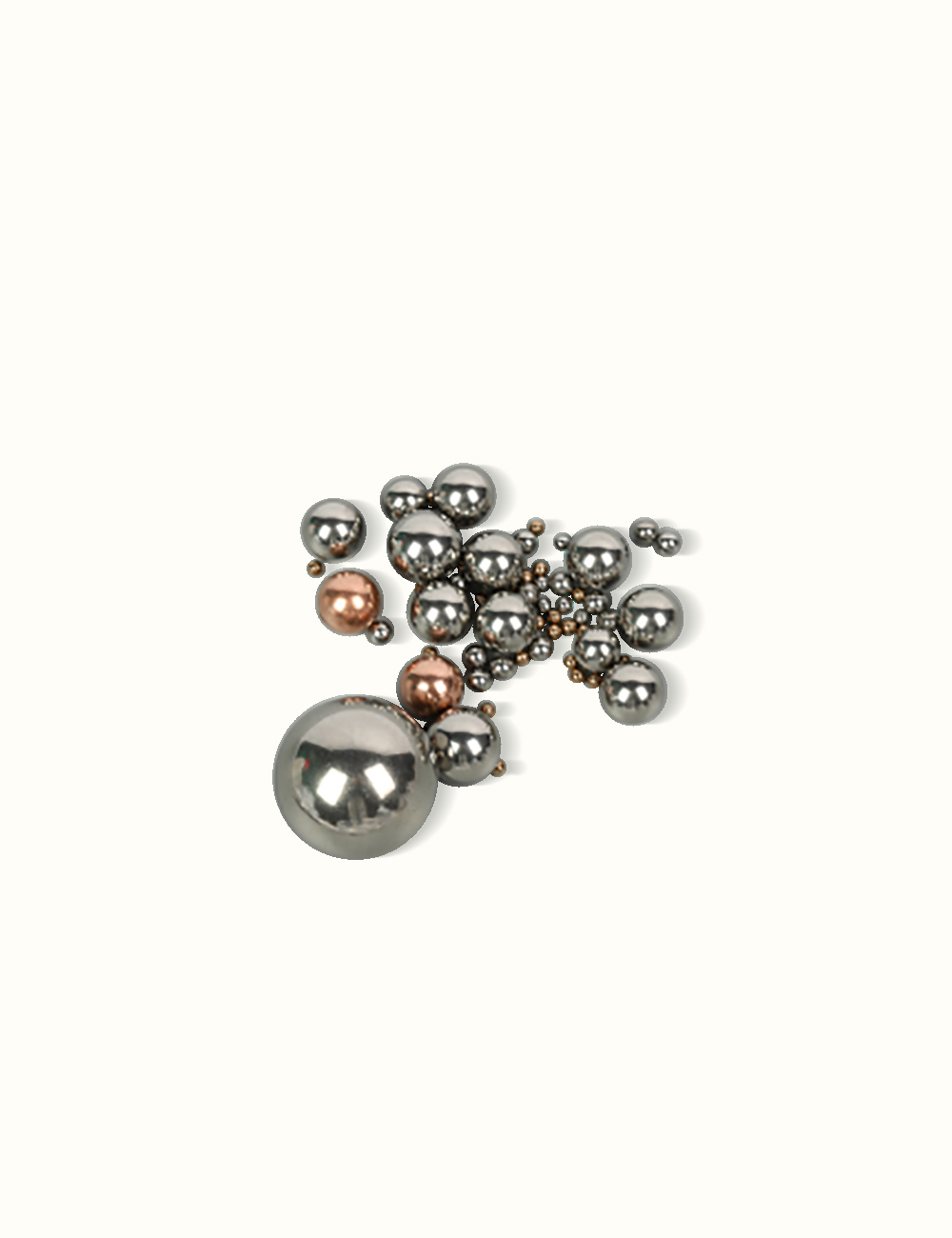

Stainless steel balls are available in different surface finishes, each of which can impact their performance in various ways. Here are some common surface finishes and their effects:

Mirror Finish: Achieved through a meticulous process of polishing, a mirror finish on stainless steel balls yields an exceptionally smooth and reflective surface, akin to a mirror. This finish not only serves an aesthetic purpose, elevating the visual appeal of the stainless steel balls, but also boasts significant functional benefits. By minimizing surface irregularities and imperfections, the mirror finish reduces areas where contaminants can accumulate, thus enhancing the balls' resistance to corrosion. The smooth surface facilitates easier cleaning and maintenance, making it particularly advantageous in industries where hygiene and cleanliness are paramount, such as pharmaceutical manufacturing and cleanroom environments. In architectural and decorative applications, the mirror finish lends a sense of sophistication and luxury, making it a popular choice for architectural fixtures, interior design elements, and high-end consumer products.

Matte Finish: Unlike the glossy surface of a mirror finish, a matte finish on stainless steel balls exhibits a low-gloss, non-reflective appearance, achieved through mechanical abrasion or chemical etching processes. This finish offers practical benefits in environments where glare reduction is essential, such as outdoor lighting fixtures or electronic displays. The textured surface of matte finishes may provide enhanced grip or friction, making them well-suited for use in ball bearings, valve components, or industrial machinery where secure handling is critical. Beyond its functional advantages, the matte finish imparts a contemporary and understated aesthetic, making it a popular choice for modern architectural designs, automotive components, and consumer electronics.

Electropolished Finish: Electropolishing is a specialized electrochemical process that selectively removes surface material from stainless steel balls, resulting in a smooth, bright finish characterized by enhanced corrosion resistance and improved cleanability. By eliminating surface imperfections, including microscopic burrs and contaminants, electropolished stainless steel balls exhibit superior resistance to corrosion, rusting, and staining, making them ideal for applications in aggressive environments such as chemical processing, marine engineering, and medical devices. The process imparts a high level of cleanliness to the surface, minimizing the risk of bacterial growth or contamination, which is particularly critical in industries like food and beverage processing, biotechnology, and pharmaceutical manufacturing. The bright and lustrous appearance of electropolished stainless steel balls makes them well-suited for decorative or architectural applications where aesthetics play a significant role.

Passivated Finish: Passivation is a chemical treatment applied to stainless steel balls to remove free iron from the surface and promote the formation of a passive oxide layer, thereby enhancing corrosion resistance. This process is essential for ensuring the long-term durability and performance of stainless steel balls in aggressive environments where corrosion is a concern, such as marine, aerospace, and chemical processing industries. By eliminating surface contaminants and impurities, passivated stainless steel balls exhibit improved resistance to rust, pitting, and crevice corrosion, prolonging their service life and reducing maintenance requirements. The passivated finish enhances the biocompatibility of stainless steel balls, making them suitable for medical implants, surgical instruments, and other biomedical applications where biocompatibility and corrosion resistance are critical factors.

Stainless steel ball for roll on bottles

Leave a Reply

Your email address will not be published.Required fields are marked

English

English 中文简体

中文简体 عربى

عربى